VIPXO Solution

A MES solution to accompany the dematerialization of your processes and increase the productivity of your equipment.

A monitoring of your production at every step, with alert notifications and personalized analysis.

Find out more

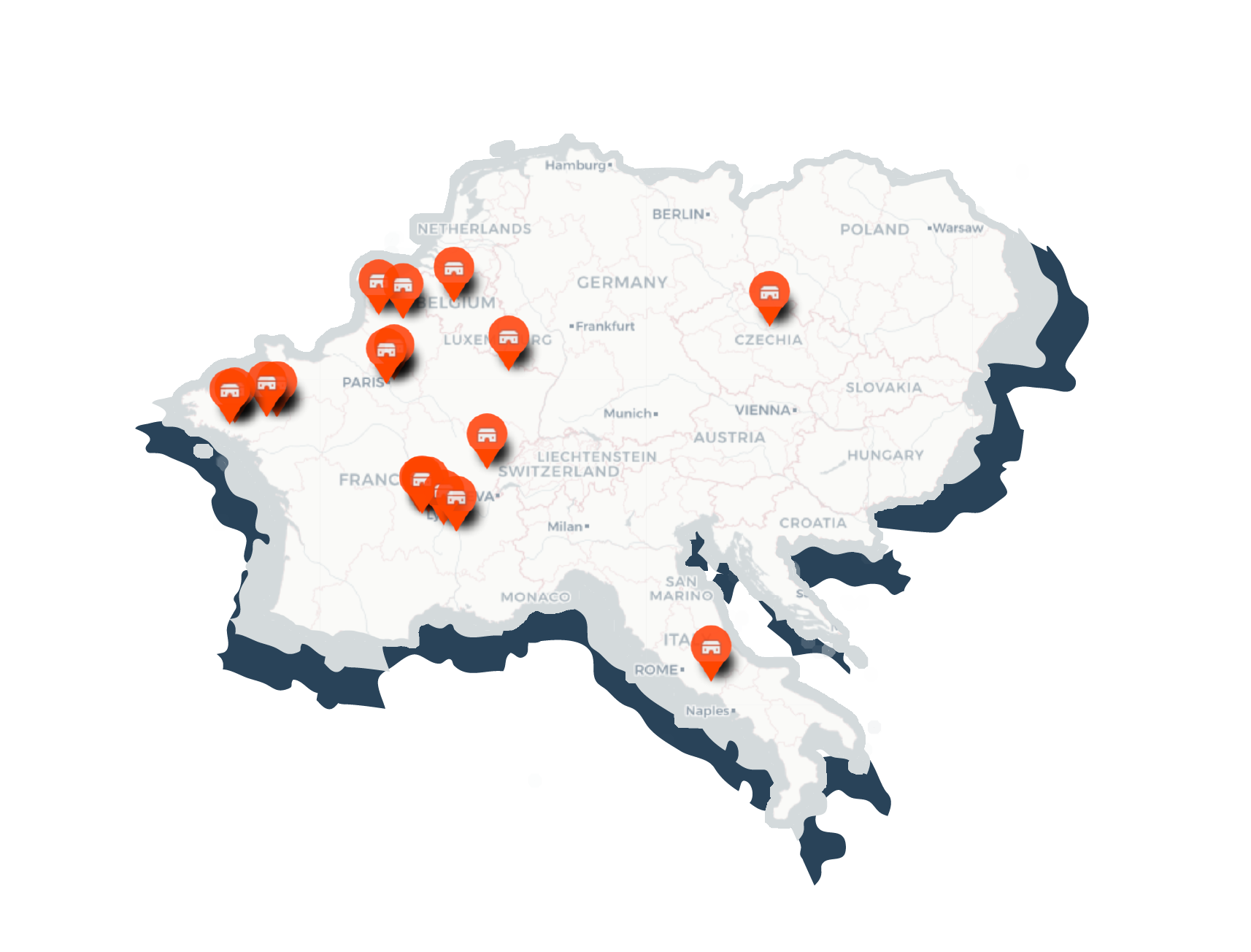

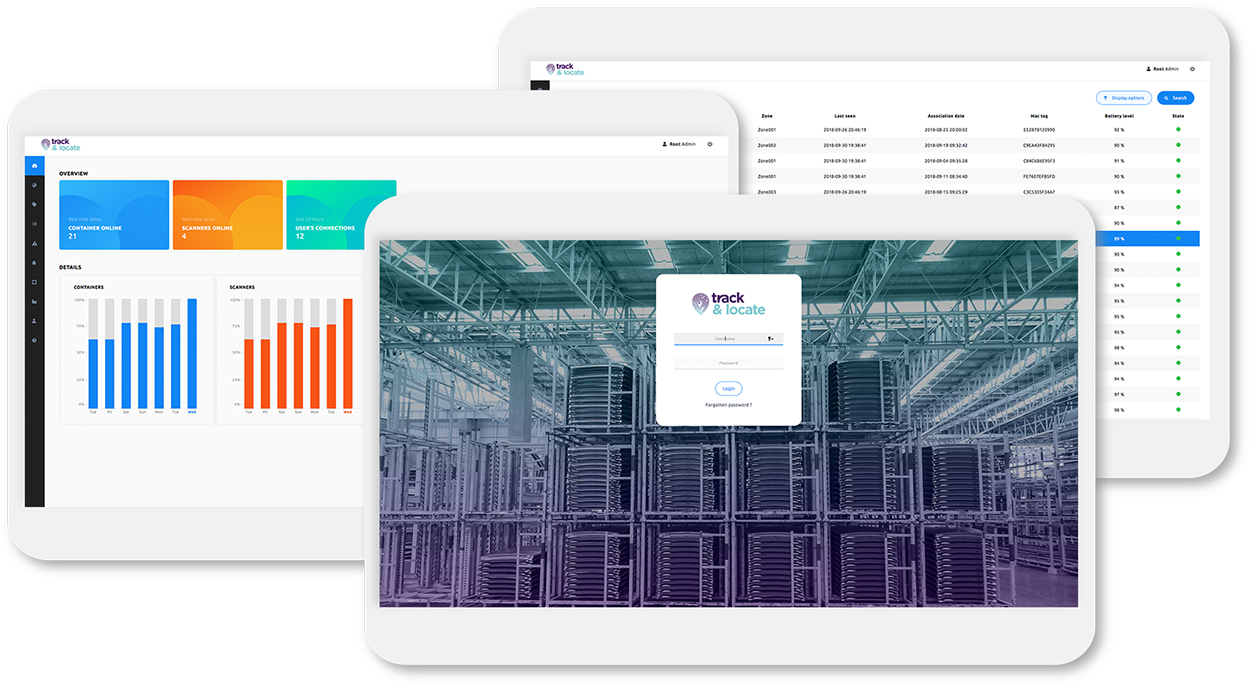

Assets Localization Engine

A highly precise and flexible assets tracking solution that interconnects easily with your existing processes.

A deployment that adapts to your needs, with a technology conceived for the industry.

Find out more

___ Our customers

MISSION STATEMENT

We aim to help our partners in the industry transition to Industry 4.0 by adapting our solutions to the existing processes that are unique to them.

We find the areas where ameliorations are possible and work with your collaborators to implement them step by step, to smooth the transition to a controlled and optimized production.

___ THE TEAM

A dynamic technical and managerial team that can rely on a long and unique experience of the industrial process:

Christophe

CORNIER

Former executive VP of ArcelorMittal and CEO of Ascometal.

Current manager of

DOCARET and YATIC.

Christophe

JUMEAU

10 years of experience in industrial IT, specialist of the 4.0 transition in the manufacturing industry.

Jean-Pierre

ALBINET

Former CTO of Alcatel-Lucent Enterprise Services, network specialist. Current CTO of Visiomed-Group.

Track and Locate is a subsidiary of DOCARET and benefits from its IT and administrative resources.

Monitoring of your

production

Data collection through means that are adapted to fit any production station

A solution that is both simple and customizable to analyze your production and generate reports

Acknowledgement of shutdownson any device, hierarchical and customizable workflow

Shutdowns alerts, after a customizable duration through text, email or phone notification

Real time visualizationof your production at every level

Quality

Management

Automatization of qualitychecks by number of pieces produced, Fabrication Order progress or machine usage

Quality forms builder by product or by machine

Fabrication

Order Management

Easy interconnection with your ERP

Generation of a Planning of Production for every station/line and workshop

Visual management of every fabrication order : state, completion, requirements, from creation to final closure

Visual

Management

Dynamic display of production, line performance and quality/safety checks for every station

Forklifts

Management

Request pickup from any device at the end of production

Forklift fleet management with the queuing of requests

Technology

Digitalization

Stock Management

Industrial Bluetooth tags

with long battery life (5 to 7 years)

Localization precision matching the needs of the project (from 50 cm to dozens of meters, depending on the deployment) in every possible environment.

Great reactivity,

able to track any moving forklift

Forklift Monitoring

during pickup and storage.

Immediate notification

to the driver in case of error.

Automatic continuous inventory

Improved monitoring of incomplete production and quality workflow

Improved traceability

thanks to a guaranteed storage by batch of your production

Already more than

15000

tags in production

Discover Us

FR

FR

EN

EN